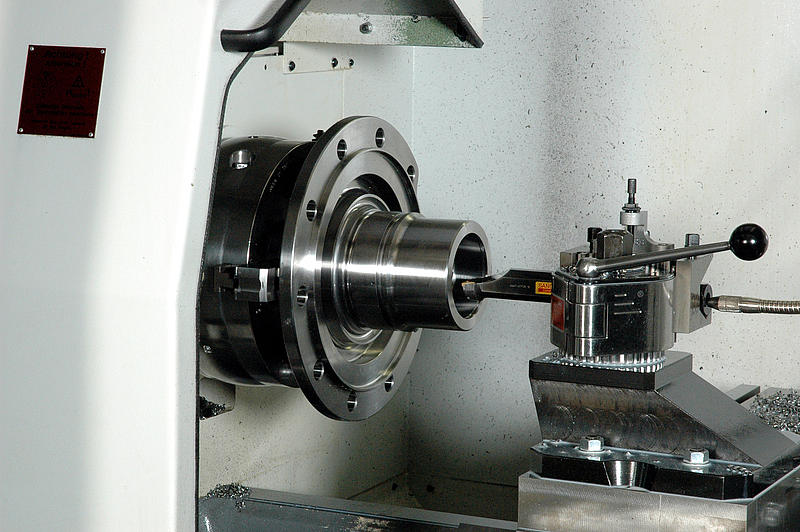

CNC milling / CNC turning

CNC milling and CNC turning for modern drive technology

The use of modern CNC technology is self-evident for Heinrich Höner in order to realise the desired precision and quality, especially in the case of individual customer requirements. The requested components for gear mechanisms and drive technology can only be produced quickly and flexibly by means of high-performing CNC systems and our highly qualified employees using CNC milling or turning.

Most modern CNC technology: Milling, turning, etc.

CNC milling is possible both vertically and horizontally, with measurements of 1600 x 600 x 700 mm and 4 axes. CNC turning, however, can only be made in the case of component parts with an external diameter of maximum 650 mm as well as a maximum length of 1000 mm. When it generally comes to the chipping of components, our CNC-operated machines perform all mechanical manufacturing methods like milling and turning, drilling and sawing as well as grinding, profile broaching and grooving for all machinable and thermosetting materials.

Modules

CNC-Milling

vertically and horizontally

1600 x 600 x 700 mm with 4 axes

CNC-Turning

external diameter of maximum 650 mm

maximum length of 1000 mm

Contact us

We are available to answer your questions, by phone or email. We would also be pleased to call you back.